Providing tools and machining services for industrial applications since 1966

Originally called Miracle Tool & Die and established in 1966 we now operate out of a twenty thousand square foot building in Lapeer Michigan. Our Decades of experience have built a wealth of knowledge on a wide range of industries including automotive, aerospace and military. From aluminum to tool-steel and copper impregnated graphite our machinists have the skills to work with a wide range of material types and cutting conditions, when combined with our large work envelope machines we can handle nearly any job no matter how large, small or complex. Nearly every aspect of the construction of our tools is done in house, from design to the final tool tryout. By performing as many aspects of the manufacturing process in house we have a wide range of machines to provide other services such as Solid Model design using Cimatron software, CNC machining from squaring to hard milling, Wire EDM including Punches, Dies and four axis cutting, Surface Grinding, Low volume production, Prototypes and fixture gauges.

Contact Us:

➤ LOCATION

Bradford Tool & Die

1130 Clark Rd. Lapeer, MI

48446 USA

☎ CONTACT

HOurs are:

mon-Fri 8am-5pm est

(810)-664-8653

Services for any industry

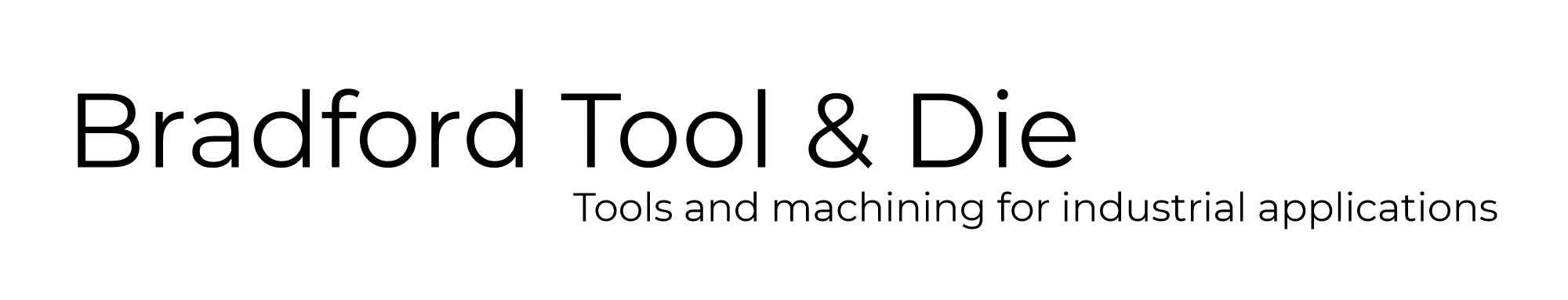

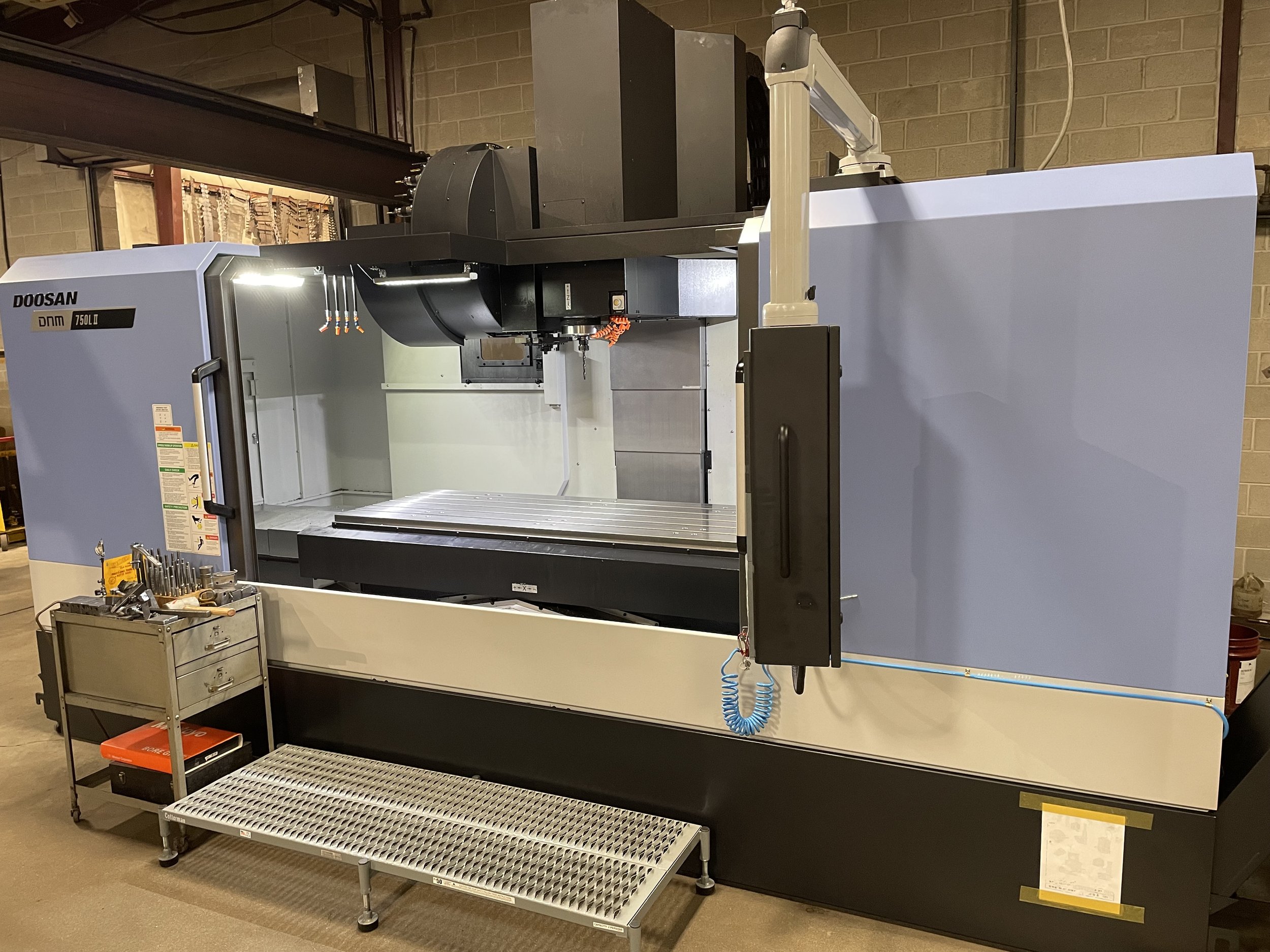

CNC Machining

With machine travels of up to 32” x 84” and experience cutting a wide range of materials we have the ability to tackle any project."

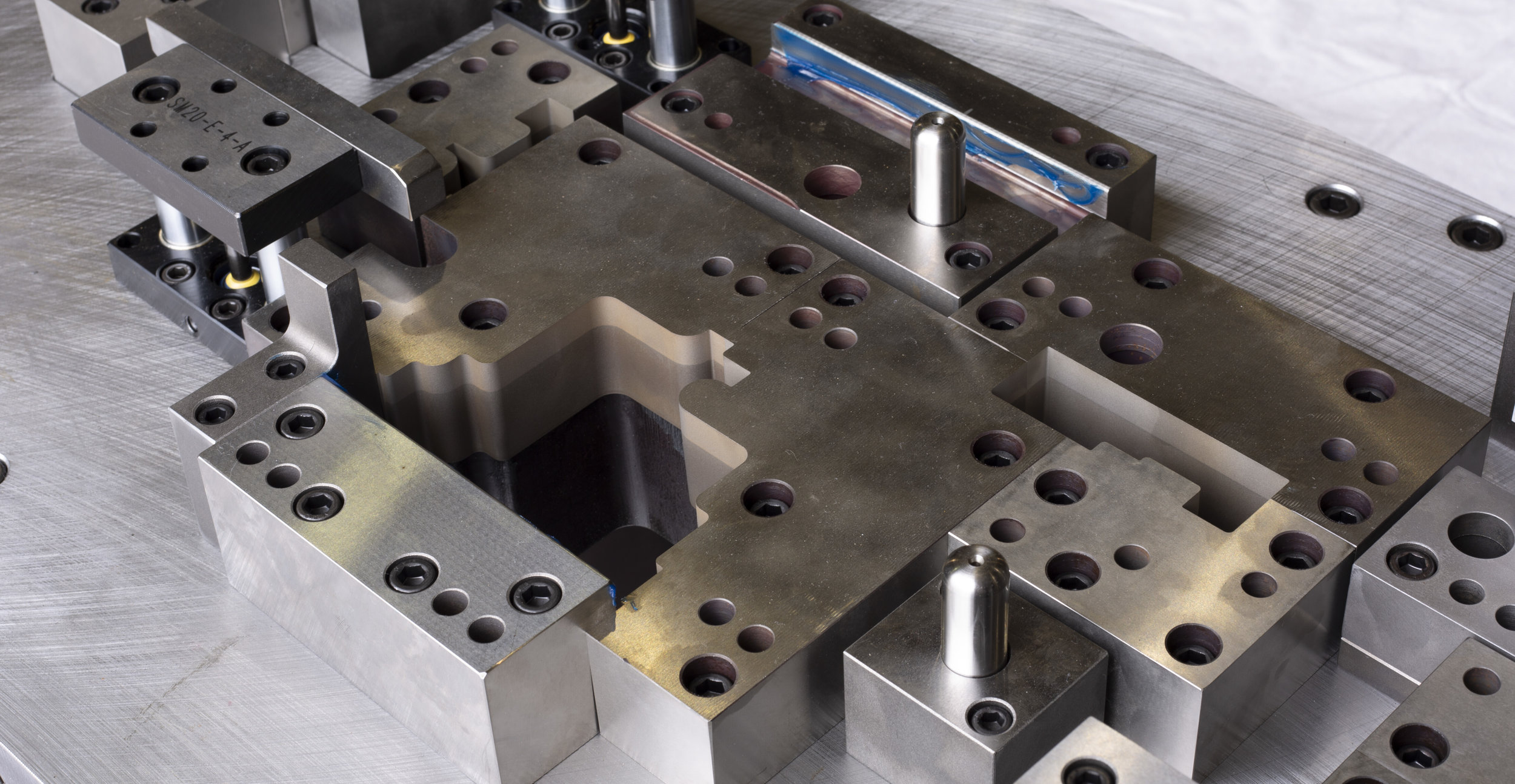

finished tool tryout

All our presses have coil handling equipment and feeders so we can test the tool under production conditions to verify the material feeds correctly through the tool at up to sixty strokes per minute. This also allows us to run the customers PPAP parts for them, freeing up their press time to run more important work.

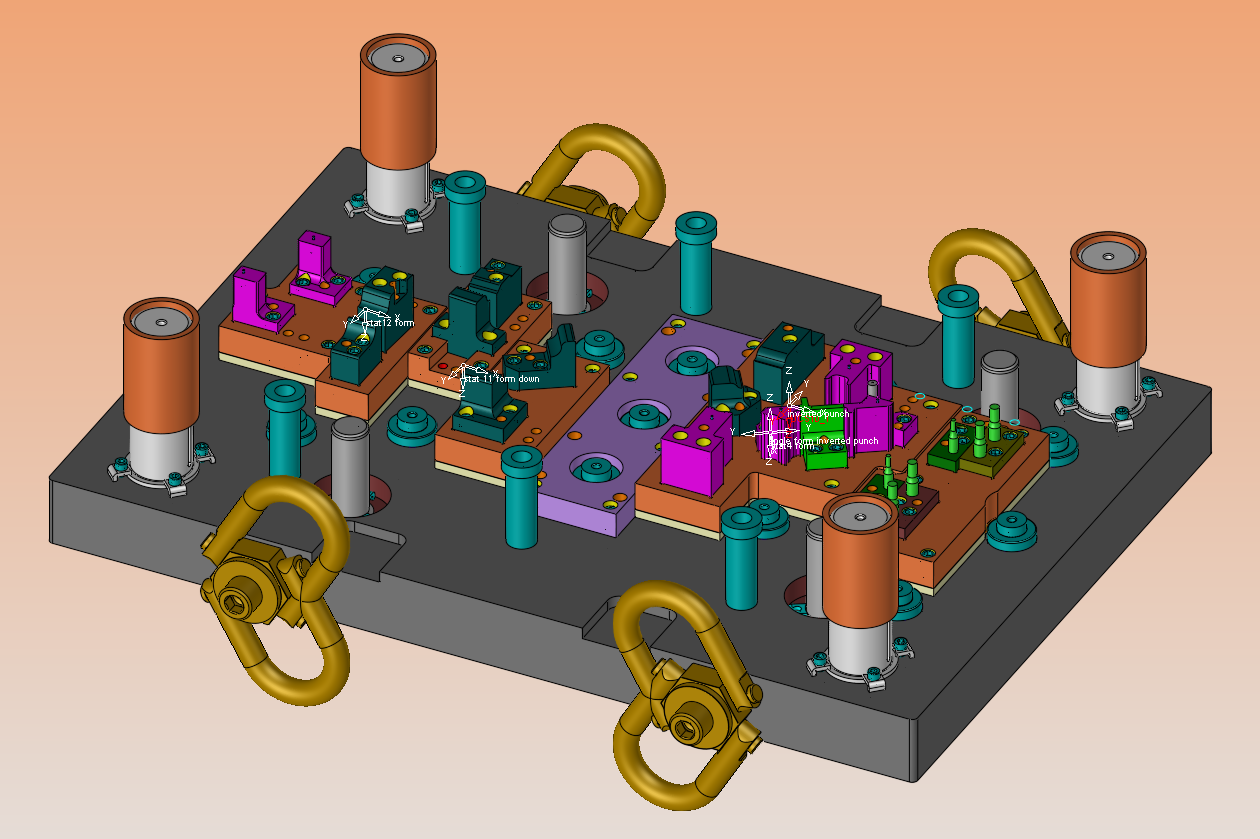

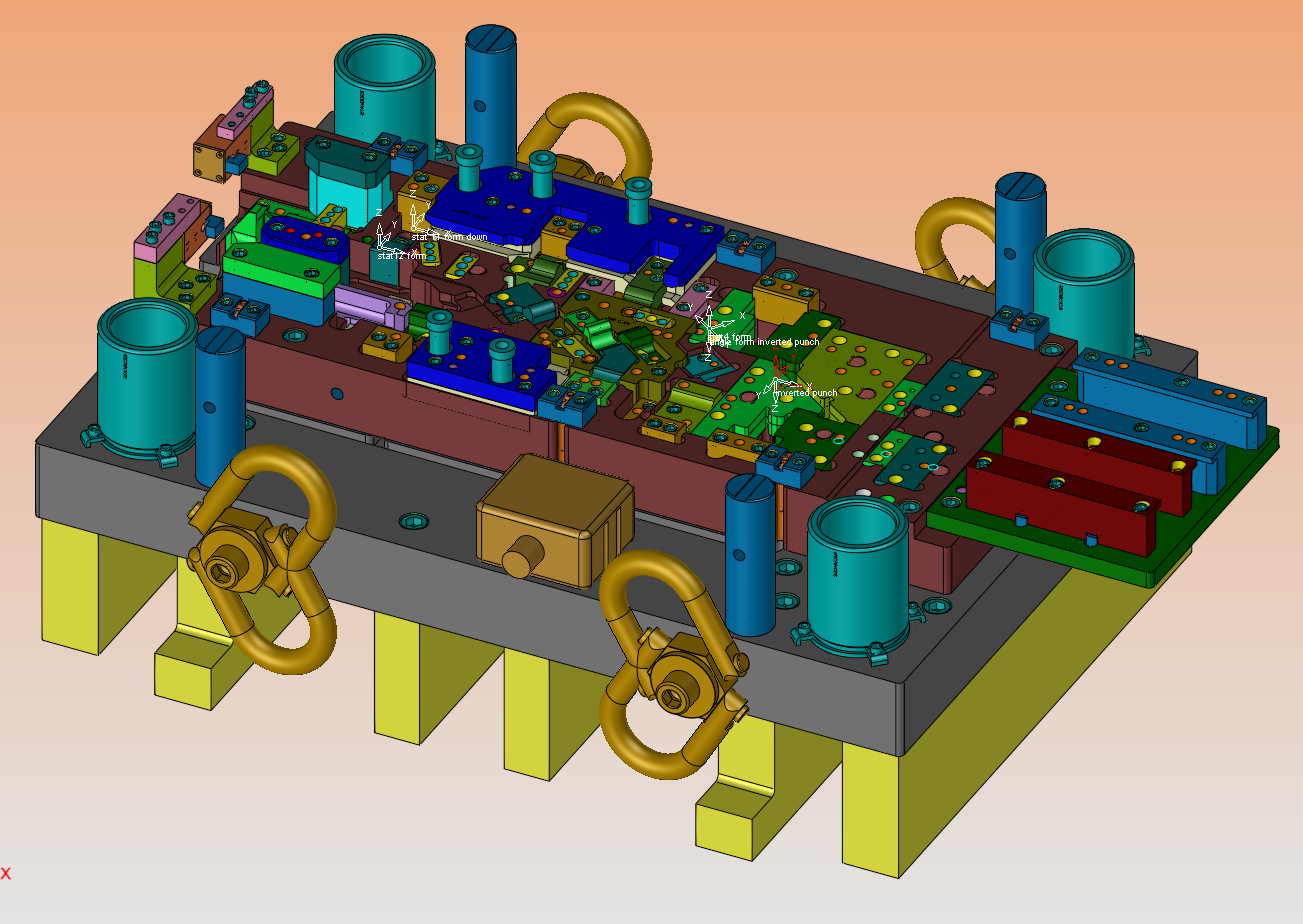

In house design and programming

Implementing solid modeling and software automation from Cimatron and OPTICAM by Camtek we deliver robust tooling at a cost competitive in a worldwide economy.

fixtures and gauges

Gauges and fixtures are made in house and can be bundled with a tool quote to further lower the overall cost of building new tooling.

Wire Edm

Our large Wire EDM’s allow us to cut parts up to 11” thick and weigh 800 kg. With our ability to cut four axis parts coupled with the size of our EDM’s as long as it conducts electricity we can cut it.

prototypes

Every part of creating prototypes, except laser cutting is done in house. We can combine tooling, fixtures and prototypes to create a truly unbeatable price.

“Perfection is not attainable, but if we chase perfection we can catch excellence.”